Please enter authorization code provided by

GreenView customer service representative

(sales@greenviewfloors.com, 770-608-3767).

AR101 Nightfall Hills

View In My Room

AR101 Nightfall Hills

View In My Room

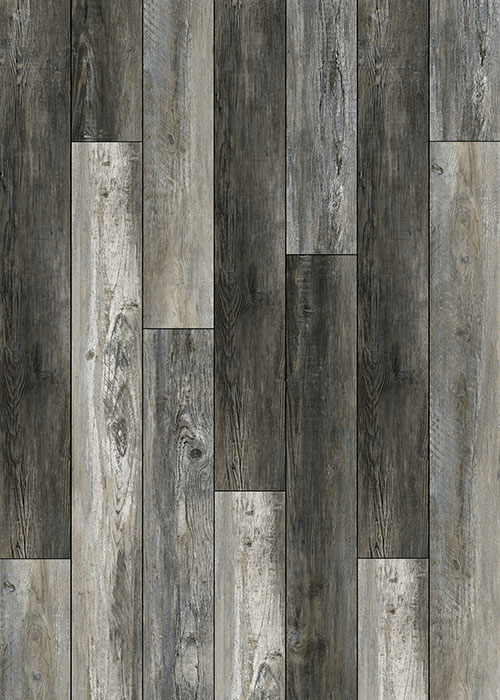

AR103 Vintage Cabin

View In My Room

AR103 Vintage Cabin

View In My Room

AR104 Natural Oak

View In My Room

AR104 Natural Oak

View In My Room

AR105 Classic Lodge

View In My Room

AR105 Classic Lodge

View In My Room

AR106 Golden Pine

View In My Room

AR106 Golden Pine

View In My Room

AR108 Berkley Oak

View In My Room

AR108 Berkley Oak

View In My Room

AR111 Sierra Sands

View In My Room

AR111 Sierra Sands

View In My Room

AR114 Rock Ferry

View In My Room

AR114 Rock Ferry

View In My Room

AR115 Fountain Hills

View In My Room

AR115 Fountain Hills

View In My Room

AR117 Vintage Hickory

View In My Room

AR117 Vintage Hickory

View In My Room

AR118 Mill Creek

View In My Room

AR118 Mill Creek

View In My Room

AR126 Sterling Oak

View In My Room

AR126 Sterling Oak

View In My Room

AR130 Lighthouse Bay

View In My Room

AR130 Lighthouse Bay

View In My Room

AR131 Brookfield

View In My Room

AR131 Brookfield

View In My Room

AR133 Canal Point

View In My Room

AR133 Canal Point

View In My Room

AR134 Placid Cabin

View In My Room

AR134 Placid Cabin

View In My Room

AR135 Logging Camp Lite

View In My Room

AR135 Logging Camp Lite

View In My Room

AR136 Everstill Forest Lite

View In My Room

AR136 Everstill Forest Lite

View In My Room

AR137 Cherry Point Lite

View In My Room

AR137 Cherry Point Lite

View In My Room

AR138 River View Lite

View In My Room

AR138 River View Lite

View In My Room

AR139 Kaneohe Bay Lite

View In My Room

AR139 Kaneohe Bay Lite

View In My Room

AR140 Catalina Lite

View In My Room

AR140 Catalina Lite

View In My Room

AR141 Petrified Forest Lite

View In My Room

AR141 Petrified Forest Lite

View In My Room

AR142 Lake Lanier Lite

View In My Room

AR142 Lake Lanier Lite

View In My Room

AR143 Cumberland Lite

View In My Room

AR143 Cumberland Lite

View In My Room

AR144 Northshire Lite

View In My Room

AR144 Northshire Lite

View In My Room

AR145 Parris Island Lite

View In My Room

AR145 Parris Island Lite

View In My Room

AR146 Oceanside Lite

View In My Room

AR146 Oceanside Lite

View In My Room

AR147 Sandy Plains

View In My Room

AR147 Sandy Plains

View In My Room

AR151 Redwood Forest

View In My Room

AR151 Redwood Forest

View In My Room

AR168 Mount Pleasant

View In My Room

AR168 Mount Pleasant

View In My Room

AR169 Cambridge

View In My Room

AR169 Cambridge

View In My Room

AR170 Carolina Hickory

View In My Room

AR170 Carolina Hickory

View In My Room

AR171 Monterrey

View In My Room

AR171 Monterrey

View In My Room

AR172 Stanford Oak

View In My Room

AR172 Stanford Oak

View In My Room

AR173 Ruby Falls

View In My Room

AR173 Ruby Falls

View In My Room

| Length | 48.03 | Width | 7.09 |

| Thickness | 5mm | Wear Layer | 20mil |

| Finishing | Wood Emboss | Edge Description | Micro Bevel |

| Sqft/Box | 23.64 | lb/Box | 40.0 |

| Box/Plt | 55 | Sqft/Plt | 1300.2 |

| lb/Plt | 2230 | Plt/FTL | 20 |

| Limited Residential Warranty |

Lifetime | Limited Commercial Warranty |

15Years |

| No. | Description | Method | Standard | Result | Performace Rating | |

| 1 | Packing Appearance | Internal | Pallets/Cartons/Labels/Inserts/Bar Codes match customer order in quality and quantity, with neat appearance. | Pass | Better | |

| 2 | Product Appearance | Internal | Material must match customer order. No print film folding, no rough bevel, no bevel with white line, no film scratch or breakage, no color difference, no wear layer bubbles, no impurities, no stains, no dents, no scratches, no broken corners, no fish eyes, no trash, no holes, no hair/ foreign subject, no overhang or uneven backpad, etc. Laser print of date/PO# and crew# present. | Pass | Better | |

| 3 | Dimensions | Length Width |

ASTM F1700 | ± 0.40 mm ± 0.10 mm |

0.03mm 0.02mm |

Best Best |

| 4 | Overall Thickness | ASTM F1700 | ± 0.10 mm | 0.02mm | Best | |

| 5 | Squareness | Length Width |

ISO 24342 | ≤ 0.25 mm ≤ 0.25 mm |

0.03mm 0.02mm |

Best Best |

| 6 | Straightness | Length Width |

ISO 24342 | ≤ 0.25 mm ≤ 0.25 mm |

0.05mm 0.01mm |

Best Best |

| 7 | Stitching Gap (mm) | EN13329 | ≤ 0.10mm | 0.02mm | Best | |

| 8 | Height Difference | EN13329 | ≤ 0.10mm | 0.03mm | Best | |

| 9 | Wear Layer Thickness | EN 429 | ± 0.02 mm | 0.01mm | Best | |

| 10 | Peel Strength of Adhesive Bonds | ASTM D903 | ≥5.5Lbs/Inch | 10.3Lbs/Inch | Best | |

| 11 | Scratch Resistance | EN 16094B | > 2500g | 4,000g | Best | |

| 12 | Micro-Scratch Resistance (A & B) | EN 16094 | MSR-B1 - B3 | MSR-B2 | Better | |

| 13 | Coating Adhesion (Cross hatch) | EN 16094B | 5B | 5B | Best | |

| 14 | Abrasion Resistance of Organic Coatings by the Taber Abraser | ASTM D4060 | No pass-fail criteria | Abrasion Wheel H-18 Load Applied 1000 Grams Number Of Cycles:14000 | Best | |

| 15 | Determination of Locking Strength for Mechanically Assembled Panels | ISO 24334 | ≥2KN/M | Long Side 5.6 KN/M Short Side 3.1 KN/M | Good | |

| 16 | Determination of Dimensional Stability and Curling after Exposure to Heat (6h - 176F) | ISO 23999 ASTM F3261 | Length mean ≦0.25% Width mean ≦0.25% | Length mean =0.02% Width mean =0.04% | Best | |

| 17 | Wear Layer Abrasion Resistance | EN 13329 (S-42, 200 cycle change) | 0.3mm wear layer IP≥1,800 cycles; 0.5mm wear layer IP≥4,000 cycles. | No abrasion through wear layer into print film upon cycle completion. | Better | |

| 18 | Density | ASTM D2395 | 1.9-2.2g/cm³ | 1.98g/cm³ | Good | |

| 19 | Phthalates | CPSC-CH-C1001-09.4 | GC-MS analysis each substance ≤ 50ppm | < 1.0pppm | Best | |

| 20 | Heavy Metal Content Analysis | ASTM F963 | Antimony < 60 ppm, Arsenic < 25 ppm, Barium < 1000 ppm, Cadmium < 75 ppm, Chromium < 60 ppm, Lead < 90 ppm, Mercury < 60 ppm, and Selenium < 500 ppm | All < 0.25ppm | Best | |

| 21 | Gloss Level (gu) | ASTM D523 | ±2gu | < ±2gu | Good | |

| 22 | Resistance to Chemicals | ASTM F925 | 0 - No change (----) 1 - Slight change 2 - Moderate change 3 - Severe change | 0 No Change | Good | |

| 23 | Determining Resistance of Synthetic Polymers to Fungi | ASTM G21 | Rating 0: No Fungal Growth on Sample Rating 1: Trace of Growth (< 10% coverage) Rating 2: Light Growth (10-30% coverage) Rating 3: Medium Growth (30-60% coverage) Rating 4: Heavy Growth (60-100% coverage) | Rating 0, No Fungal Growth on Sample | Best | |

| 24 | Smoke Density (Non-Flaming) | ASTM E662 | ≦450 | 291 | Best | |

| 25 | Smoke Density (Flaming) | ASTM E662 | ≦450 | 237 | Best | |

| 26 | Calculated Sound Transmission (STC) | ASTM E90-09 (2016) ASTM E413-16 | No pass-fail criteria | 52 | Good | |

| 27 | Impact Sound Reduction (IIC) | ASTM E492-09 ASTM E989-18 | No pass-fail criteria | 62 | Good | |

| 28 | Short-Term Indentation and Residual Indentation of Resilient Floor Covering | ASTM F1914 ASTM F3261 | ≤ 0.007 inch Surface Integrity: No puncture through wear layer/print film into rigid core. | 0.002 inch No puncture through wear layer/print film into rigid core. | Best | |

| 29 | Static Load Limit | ASTM F970 | Max loading: 250psi Max residual indent: 0.005 inch | 0.003 Inch @ 250psi | Good | |

| 30 | Heat Stability of Resilient Flooring by Color change | ASTM F1514 | < 8.0 ΔE | 0.05-0.19 ΔE | Best | |

| 31 | Light Stability of Resilient Flooring by Color change | ASTM F1515 | < 8.0 ΔE | 0.29-0.46 ΔE | Best | |

| 32 | Static Coefficient of Friction | ASTM C1028 | ≥ 0.60 for dry surfaces ≥ 0.53 for wet surfaces | Dry 0.69 Wet 0.56 with 50lbs load | Good | |

AA001 Lake Lanier

View In My Room

AA001 Lake Lanier

View In My Room

AA002 Kaneohe Bay

View In My Room

AA002 Kaneohe Bay

View In My Room

AA003 Mount Pleasant

View In My Room

AA003 Mount Pleasant

View In My Room

AA004 Carolina Hickory

View In My Room

AA004 Carolina Hickory

View In My Room

AA005 Monterrey

View In My Room

AA005 Monterrey

View In My Room

AA006 Brookfield

View In My Room

AA006 Brookfield

View In My Room

AA007 Placid Cabin

View In My Room

AA007 Placid Cabin

View In My Room

AA008 Berkley Oak

View In My Room

AA008 Berkley Oak

View In My Room

| Length | 60" | Width | 9" |

| Thickness | 6.5mm | Wear Layer | 22mil |

| Finishing | Wood Emboss | Edge Description | Micro Bevel |

| Sqft/Box | 22.44 | lb/Box | 48.27 |

| Box/Plt | 52 | Sqft/Plt | 1167 |

| lb/Plt | 2545 | Plt/FTL | 17 |

| Limited Residential Warranty |

Life Time | Limited Commercial Warranty |

15 Years |

| Items | Standards | Requirements | Result |

| GreenGuard Gold Certified |

UL 2818 - 2013 Gold Standard for Chemical Emissions for Building Materials, Finishes and Furnishings | Refer to Standards | Pass |

| Floorscore Certification |

SCS-EC10.3-2014v3.0 | Refer to Standards | Pass |

| CE Certification | EN14041 | Refer to Standards | Pass |

| Fire resistance | EN 9239-1 EN ISO11925-2 EN 13501-1 |

Critical Fluxf≥8.0kW/m2 Fs≤150mm within 20s Smoke≤750% minutes |

Bfl-S1 |

| Phthalate tests (DBP/BBP/DEHP/DINP/ DNOP/DIDP) |

EN 14372:2004 | N/A | Free |

| Dimension stability | ASTM F2199-09(R2014) | ≦0.25% | Manufacturing direction:-0.046% Across-manufacturing direction:-0.009% |

| Seam strength | EN 684:1995 | N/A | Ave.:360N/50mm Pass Min.:330N/50mm |

| Residual indentation (%) | ASTM F1700-13a & ASTM F1914-07(2011) |

Average value≦8 Individual value≦10 |

0.4 Pass |

| Resistance to chemicals | ASTM F1700-13a & ASTM F925-13 |

No more than a slight change in surface dulling,surface attack,or staining | No change in surface dulling,surface attack,or staining was detected |

| Heat stability | ASTM F1514-03(R2013) | △E*ab< 8 | △E*ab=0.67 Pass |

| Static loading | ASTM F970-17 | N/A | 0.04mm Pass |

| Soluble heavy metal contents test | ASTM F963-16(Clause 8.3) | N/A | Free |

| Large ball impact resistance | NALFA/ANSI LF-01-2011 | N/A | No cracks or fractures occurred at the height of 2500mm |

| Static Electrical Propensity | EN 1815:2016 method A | ≦2kV | 0.2kV |

| Sound Transmission Class | ASTM E90-2009(R2016) ASTM E413-10 |

N/A | STC=68 |

| Formaldehyde | ISO 17226-1:2008 | N/A | Free |

| Surface Bond | NALFA/ANSI LF-01-2011 | N/A | 1.14MPa Pass |

| Resilient floor covering Determination of peel resistance | EN ISO 24345:2012 | ≥54N/50mm | Longitudinal direction:95N/50mm Cross direction:95N/50mm |

| Castor chair Resistance(25000 Cycles) | NALFA/ANSI LF-01-2011 ISO4918:2016 |

N/A | No damage was found after test |

| Thermal conductivity | EN 12667:2001 | N/A | 0.154 W/(m.K) |

| Thermal Resistance | EN 12667:2001 | N/A | 0.033(m2.K)/W |

| Colour Fastness | EN ISO 105-B02:2014 | N/A | Grade 6 |

| Curling | ISO 23999:2008 | N/A | Average: 0.5mm Pass |

| Locking strength | ISO 10582:2017 Annex D | Class 32, type I:≥1.5kN/m |

Long side(X): 7.6 kN/m Short side(Y): 6.3 kN/m Pass |

| Resistance to staining | ISO 26987:2008 | N/A | Index 0: Not affected Pass |

| Slip resistance (oil-wet ramp test) |

DIN 51130:2014-02 | N/A | Critical angle of inclination: 14.8°Classification: R10 Pass |

| Resistance to bacteria | ISO 846-1997 Method C | N/A | Assessment of bacteria growth: 0 Pass |

| Scratch Resistance | EN 16094B | >2,500g | 3,500g |

Alta Gunstock

Alta Gunstock

Ashland Beige

Ashland Beige

Black Forest Oak

Black Forest Oak

Espresso

Espresso

Gunstock

Gunstock

Millstone

Millstone

Sierra

Sierra

Woodland

Woodland

Farmhouse Oak

Farmhouse Oak

Appalachian Gray

Appalachian Gray

Arlington

Arlington

Ashed Oak

Ashed Oak

Asheville

Asheville

Aurora

Aurora

Austin

Austin

Bonita Falls

Bonita Falls

Carmel Valley

Carmel Valley

Carolina Pine

Carolina Pine

Charleston

Charleston

Cherry Point Lite SE

Cherry Point Lite SE

Clarksville

Clarksville

Columbia

Columbia

Dallas

Dallas

ElPaso

ElPaso

Evening Glade

Evening Glade

Fieldstone

Fieldstone

Glendale

Glendale

Greenville

Greenville

Greystone

Greystone

Hanover

Hanover

Havasu

Havasu

Houston

Houston

Impact Desert Sand

Impact Desert Sand

Impact Moondust

Impact Moondust

Kingston

Kingston

Lexington

Lexington

Majestic Landmark

Majestic Landmark

Majestic Millstone

Majestic Millstone

Majestic Olympia

Majestic Olympia

Majestic Redwood

Majestic Redwood

Majestic Timeless

Majestic Timeless

Majestic WestPort

Majestic WestPort

MeadowDale

MeadowDale

Mesa

Mesa

Mojave

Mojave

Moon Lake

Moon Lake

Moonshine Valley

Moonshine Valley

Peoria

Peoria

Phoenix

Phoenix

Pleasant Cabin

Pleasant Cabin

Pleasant Valley

Pleasant Valley

Providence

Providence

Reno

Reno

Rock Creek

Rock Creek

San Marcos

San Marcos

Savannah

Savannah

Scottsdale

Scottsdale

Smokey Creek

Smokey Creek

Spring Valley

Spring Valley

Stillwater

Stillwater

Sun Lake

Sun Lake

Sunshine Coast

Sunshine Coast

Tahoe

Tahoe

Tuscan Oak

Tuscan Oak

Twilight

Twilight

Wilmington

Wilmington